The Biomedical Device Laboratory synthesizes and characterizes a range of polymers with a focus on shape memory polymers (SMPs), “smart” materials that are capable of shape change. Our SMPs can be synthesized into many geometries and morphologies. In addition to polymer synthesis, we explore techniques, such as nanoparticle incorporation and surface modification, to impart additional functionalities, including radiopacity or degradation resistance.

Porous SMP scaffolds are synthesized with tunable pore morphology and thermo-mechanical response to match properties to specific application needs. Variables such as crosslink density, hydrophobicity, and pore size effect the shape memory behavior of the polymer to enable actuation time frames between 30 seconds and 30 minutes.

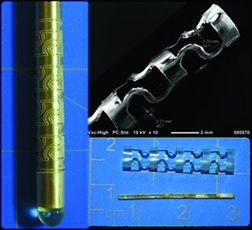

Thermoplastic SMPs are synthesized that can be crosslinked post-polymerization via electron beam or thiol-ene click chemistry. This polymer library has exceptional tunability in terms of mechanical, thermal, and shape memory properties. These materials can be processed via injection molding, electrospinning, or foaming to enable control over scaffold material properties and network architecture. The high tunability of this system enables its future translation into a range of applications, including neural interfaces, wound dressings, and stents.

The backbone, bulk, or surface of synthesized polymers are modified to alter or enhance properties. The polymer backbone chemistry is altered to eliminate or increase degradation rates. Nanoparticles have been incorporated into SMP foams to provide radiopacity and improve mechanical properties. Using plasma modification, we alter the surface properties to tune shape memory expansion kinetics, open pores in SMP foams, and enable further functionalization of the surface chemistry.